And god forbid if you want to go back and make significant changes in the tree. Let's be honest, how much of your time in SW is spent fixing a broken feature tree? I would argue up to 20% of an entire project can be spent rebuilding and fixing broken features. And it's true, in SW this is important because if you don't, the whole tree can break randomly if a sketch becomes undefined and conflicts with future features.

#Fusion 360 free license how to

When being taught how to model in SW, my teachers went to great lengths to make sure we fully constrained every sketch. It's all about managing the feature tree and making sure it is efficient and well built. It's parametric solid modeling, capably done. Now to go into a bit more detail about what SW is good at, and what makes it unique. A lot of businesses use SW, so it's a useful tool to have under your belt, but at some point if you're serious about CAD work you're going to have to step up. I know this might sound like a diss, but it's not. Having said that, a HUGE swathe of mid and low-tier companies use SW. No self-respecting top-tier design company uses SW. Off the top of my head, Apple, Dyson and Mercedes all use Alias and NX for different stages in the design process.

To give you some perspective, none of the big serious design companies use SW. For that, you have to step up to Alias (for A-surface modeling), CATIA or NX. SW simply doesn't have the capability to design a car, or many other objects. If you don't know what those things are, I might cover them in more detail in another article, but for now - it's basically the difference between the surfacing seen on a poorly designed hair dryer versus the smooth, flawless curves on a Mercedes. It is not designed for class-A surfacing or critical curve control. It is designed to make simple, solid body objects and to make functional, highly controlled assemblies with those parts.

The devil you know is better than the devil you don't.įrom an industry perspective, SW is an entry level CAD system. I think this is the default position of a lot of SW users. A lot of my peers complained about rebuild times and features that would fail for inexplicable reasons, but I often was able to find a way around these issues and would defend it often because I hadn't used anything else. This is the system I learnt CAD on, and when I was using it, I loved it.

Not because it was good, but because of an entrenched user base and aggressive sales.

#Fusion 360 free license registration

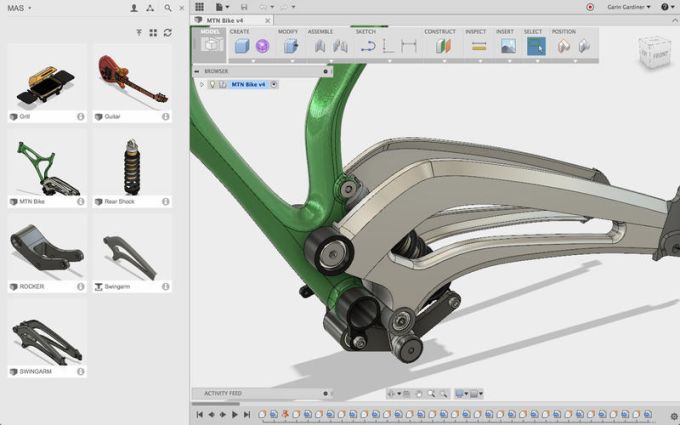

I'll maybe try the CAD functionality this weekend.Īfter seeing all the fancy features during my cursory look, the "FREE" part sounded to good to be true so I went through the registration process, selected the free option and the "30 days evaluation" part in the title bar disappeared so apparently I'm now the proud owner of a free Fusion360 Ultimate.10 years ago, Solidworks cornered the education and small business markets. It's also supports something called 3+2 (5-axis positioning) for both 2.5 and 3d strategies which might be handy of you have a 4th axis on your machine. Its got sort of a Google Sketch-up look and feel. The tutorials worked flawlessly and nothing crashed or broke and its relatively easy to get going, so I like it so far. Definitely worth a look for 2.5 and 3D CAM as its got a lot of the high end CAM strategies like Adaptive Clearing, Pencil, Scallop, Spiral, Radial etc. Installed it and played a bit by working through some 2.5D and 3D CAM tutorials and wow, I'm quite impressed.

0 kommentar(er)

0 kommentar(er)